Our Products

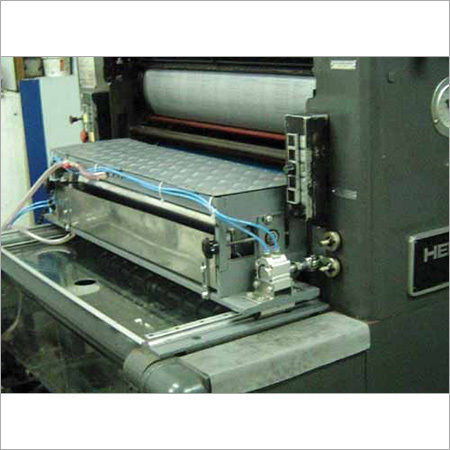

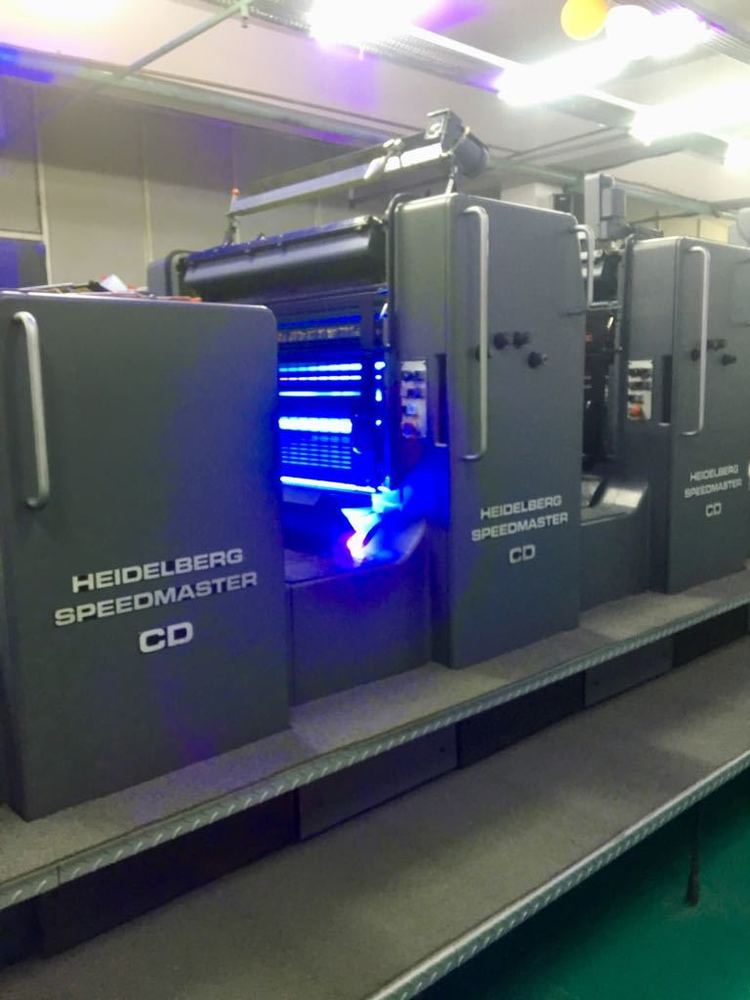

UV Coating Machine Heidelberg

By following the heavy duty construction finest grade of UV Coating Machine Heidelberg is manufactured. This machine is equipped with independent AC Motor and frequency drive, the pneumatic impression is synchronized with main machine as well. Offered machine gives high production and is easy to register. It can be fitted on sheet fed offset of any make and size. This grade of UV Coating Machine Heidelberg has number of printing features of the main machine which remains unchained as the system is independent. Our esteemed clients can avail this well functioning machine in different technical specifications as per their requirements at highly affordable market rates.

Features:

- Heavy duty construction

- Manual retraction system to change between printing and coating

- Independent AC motor and frequency drive

- Pneumatic Impression synchronized with main machine

- Varnish recirculation system with drip tray

Advantages:

- Easy to register and high production

- Full as well as Spot Varnishing possible

- Printing features of the main machine remains unchanged, as the system is independent

- The total investment is negligible as compared to other options

- Can be fitted on sheet fed offset of any make and size

- Custom engineered to fit individual press

Options:

Chamber doctor blade system

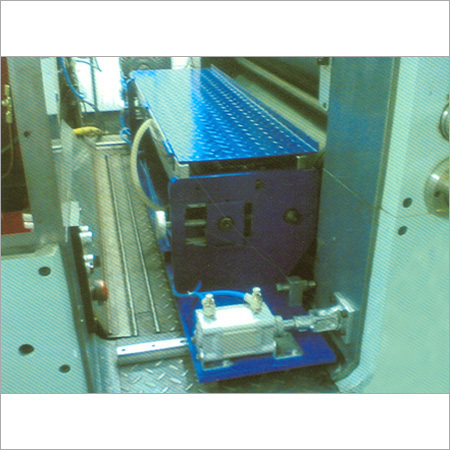

UV Coating Machine Komori

- Energy efficient

- Simplified handling

- Longer functional life

- Robust construction

- Heavy duty construction.

- Manual retraction system to change between printing and coating.

- Independent AC motor and frequency drive.

- Pneumatic Impression synchronized with main machine .

- Varnish recirculation system with drip tray.

Advantages:

- Uniform coating thickness with greater efficiency and repeatability.

- Easy to register and high production.

- Full as well as Spot Varnishing possible.

- Printing features of the main machine remains unchanged, as the system is independent.

- The total investment is negligible as compared to other options.

- Can be fitted on sheet fed offset of any make and size.

- Custom engineered to fit individual press.

Options:

Chamber doctor blade system

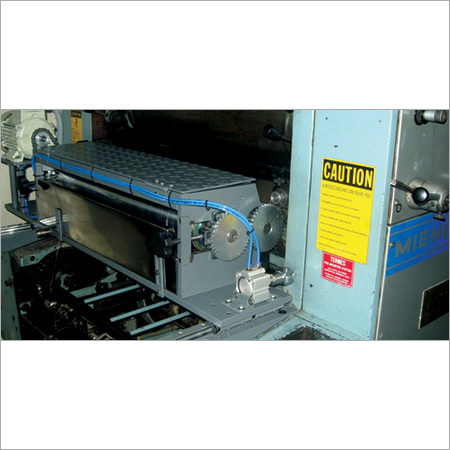

UV Coating Machine - Planeta

Features:

- Heavy duty construction

- Manual retraction system to change between printing and coating

- Independent AC motor and frequency drive

- Pneumatic Impression synchronized with main machine

- Varnish recirculation system with drip tray

Advantages:

- Uniform coating thickness with greater efficiency and repeatability.

- Easy to register and high production.

- Full as well as Spot Varnishing possible.

- Printing features of the main machine remains unchanged, as the system is independent.

- The total investment is negligible as compared to other options.

- Can be fitted on sheet fed offset of any make and size.

- Custom engineered to fit individual press.

Options:

Chamber doctor blade system

UV Coating Machine Roland

- Heavy duty construction

- Manual retraction system to change between printing and coating

- Independent AC motor and frequency drive

- Pneumatic Impression synchronized with main machine

- Varnish recirculation system with drip tray

Advantages:

- Uniform coating thickness with greater efficiency and repeatability.

- Easy to register and high production.

- Full as well as Spot Varnishing possible.

- Printing features of the main machine remains unchanged, as the system is independent.

- The total investment is negligible as compared to other options.

- Can be fitted on sheet fed offset of any make and size.

- Custom engineered to fit individual press.

Options:

Chamber doctor blade system

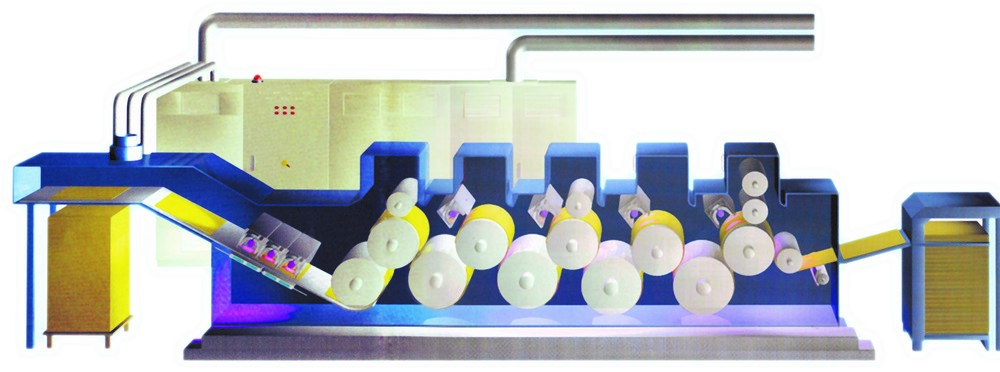

INTERDECK/END OF PRESS UV CURING SYSTEM

We have been actively engaged in the supplying of the supreme grade of

Interdeck / End Of Press UV Curing System which consists pneumatically operated shutter UV cassettes, air and water cooled UV cassettes along with a HMI and PLC controlled panel. In this system all operational and status function integrated on HMI screen. Integration of this panel with main machine is done for activation of shutter system whereas the reduction takes place in output power of UV lamps. Interdeck / End Of Press UV Curing System has overheating safety system for cassettes. It is mainly used in packaging industry.

Features:

- Pneumatically operated shutteres UV cassettes

- Air and water cooled UV cassettes

- UV lamp- 300-400 W/Inch

- Over heating safety system for cassettes

- HMI and PLC controlled panel

- All operational and status function integrated on HMI screen. Integration of panel with main machine for activation of shutter system and reduction in output power of UV lamps.

Optional Equipment:

- Electronic Power Supply for UV Lamp

Applications:

- For Full/Spot UV coating and frip off coating on offset machine with coater

- Sheet-feed offset machine-for printing on MET-PET, PP, PVC and other non absorbent surfaces

- Narrow, wide web Flexo machines

- Rotogravure machine

UV curing is a printing technology used mainly in packaging industry, as it can be applied on any material. This printing technology is employed for creating attractive packing, so that market value of the packaged material can be enhanced. Our company, Grafik Machinery International, makes available interdeck/ end of press UV curing system, which can be attached to offset machine of any make and size. UV inks can be dried instantly with the installed dried between the printing units of a press. UV curable inks are ideal for printing on non-absorbent surface. Interdeck/ end of press UV curing system cures the first UV coat before applying the second one in case when special effect abrasive UV coating is to be applied on the printed surface.

LED UV System

Advantages:

- Low Operating Temperatures

- Energy Savings up to 75%

- Mercury and Ozone Free

- Suitable for Heat Sensitive subsrates also.

- Flexible Curing widths / Scalable

- Better Adhesion and Curing Capabilities

- Increased Production quality

Features:

- High peak Irradiance

- Air and Water cooled system

- Lamp life of upto 5,000 hrs.

- Easy Maintenance

- Operates on single phase

- Instant Start & Stop

- Compact Size, makes installation easier

- Width wise zone control

Applications :

- Sheet fed Offset Machines

- Flexo Machines- Narrow and wide web

- Screen printing machines

- UV Coating machines

Comparision Table:

| Features | UV-LED | UV-MERCURY |

| Lamp life | upto 5,000 hrs | 1000-1500 hrs |

| Heat Generation | No | High |

| Intensity control | 0-100% | 10-100%(with EPS) |

| Size | Compact | Heavy |

| Start-up time | Instant | 3-4 minutes |

| Energy consumption | Low | High |

| Environment Friendly | Yes | No |

LED UV System is put to use when inks, paints or clear coats are to be instantly dried, or adhesives to be cured in bonding or sealing processes. Ultraviolet energy is used for changing a liquid into a solid. A polymerization reaction is caused as UV energy absorbs, which changes the UV material into solid. UV LED curing method is better than any traditional drying method, as it delivers several benefits, for instance environmentally friendly, high-end functionality, increased efficiency, ensured safety, and long service life. In comparison to UV-mercury, UV-LED has better lamp life, more compact size, instant start-up time, lower energy consumption, and doesn't generates heat. The system is mainly used with special printing and coating machines. Companies whose requirements are quick and efficient curing in applications that involve printing inks,coatings and adhesives, can install LED UV System.